DDD-F-416F

headings beginning immediately below the upper grommet on Class 2 headings, and in

corresponding position on all other Type I headings. As an alternate, heat transfer marking

conforming to Type III of MIL-DTL-32075 may be used for flags with Type I headings. Both

types of marking shall contain information required by Class 5 labels and shall be colorfast to

accelerated weathering when tested as specified in 4.3.2.

3.8.2 Marking for Type II headings. For flags with Type II headings, the contractor shall affix a

label of woven cloth suitable for marking adjacent to the top leather tab. The label shall contain

the stock number, nomenclature, contract number, and date. When required by the

Government (see 6.2), the words "U.S. PROPERTY" shall be stamped on the heading of the

flag.

4. QUALITY ASSURANCE PROVISIONS.

4.1 Responsibility for inspection. Unless otherwise specified in the contract or purchase order,

the contractor is responsible for the performance of all inspection requirements as specified

herein. Except as otherwise specified in the contract or purchase order, the contractor may use

his own or any other facilities suitable for the performance of the inspection requirements

specified herein, unless disapproved by the Government. The Government reserves the right to

perform any of the inspections set forth in this specification where such inspections are deemed

necessary to assure that supplies and services conform to prescribed requirements.

4.2 First article inspection. When a first article is required, inspection shall be made on a

completely fabricated flag or flags, the number of which shall be determined by the contract or

purchase order, for all provisions applicable to end item examination and tests.

4.3 Quality conformance inspection. Inspection shall be in accordance with ANSI/ASQC Z1.4

and the provisions set forth herein, except as otherwise directed by the contract or purchase

order (see 6.2).

4.3.1 Certificate of compliance. Components and materials may be accepted on the basis of a

contractor's certificate of compliance (COC) for the requirements in Section 3 of the

specification. When requested by the government, the contractor shall provide actual test,

inspection, or other verifiable data to support the COC.

4.3.2 Testing of components. Testing shall be performed on the components listed in Table III

for the characteristics shown therein. The inspection level shall be S-1 and the AQL shall be 6.5

test failures per 100 units. The unit of product to be tested shall be as stated in parentheses in

the "component" column unless otherwise specified by the selected test method.

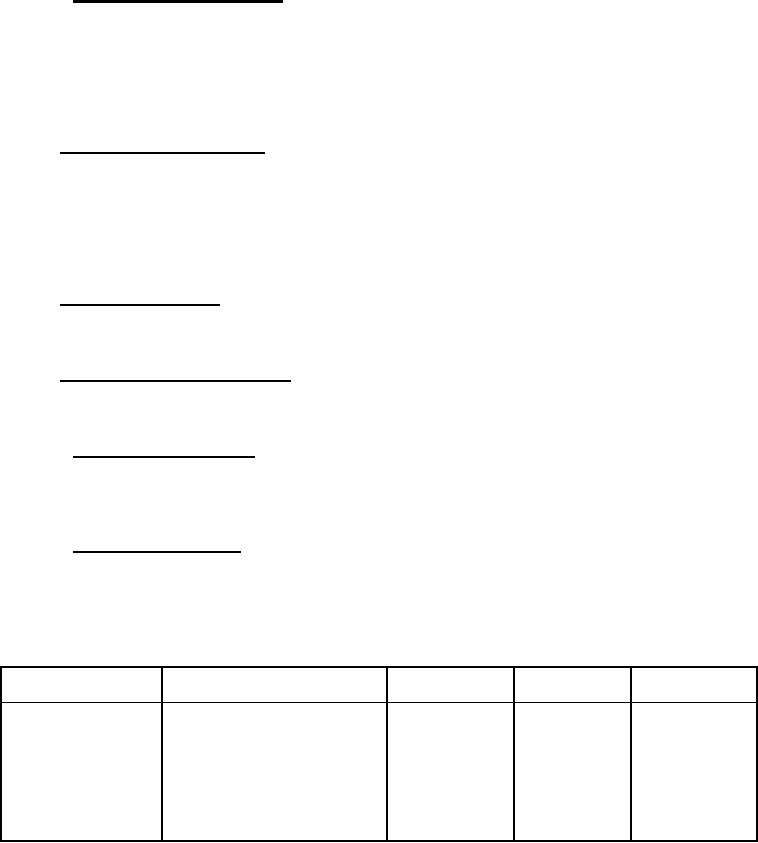

TABLE III. Testing of Components.

REQUIREMENT

TEST

RESULTS

COMPONENT

CHARACTERISTIC

PARAGRAPH

METHOD

REPORTED AS

Nylon or polyester

rope (10 ft min.)

Material identification

3.3.6

ASTM-D276

pass/fail

CI-1500,

Breaking strength

3.3.6

paragraph 9

nearest 1 lb.

Minimum 5/16" diameter for

Visual using

Type 1, Class 3 headings

3.3.6

1/16" scale

pass/fail

14

For Parts Inquires call Parts Hangar, Inc (727) 493-0744

© Copyright 2015 Integrated Publishing, Inc.

A Service Disabled Veteran Owned Small Business